Page 92 - Apraava Energy Report_01-73

P. 92

92 Energy in action

Key health & safety initiatives

1. ‘Operationalise HSSE drive’ for evaluating the 5. Fire protective blanketing on cable trays at the Coal

effectiveness of 12 key management control procedures Handling Plant (CHP)

by a cross-functional team under the mentorship of heads 6. Use of Phased Array Ultrasonic Testing to avoid radiation

of departments hazards during unit overhauling

2. Implementation of ‘field severity assessment’ for the 7. Improvised safety induction facility with advanced

entire plant to identify the focus areas of the plant at risk audio-visual training kiosk for general visitors

behaviour and unsafe conditions 8. Digitisation: e-SAFE mobile & web-based application

3. Improvement in the effectiveness of HSSE discussions for launch for reporting and monitoring field safety

different meetings such as morning progress review meeting, observation.

HSSE Apex Committee meeting, monthly operational review 9. Development of confined space fitness testing facility for

meeting, department HSSE triangle meeting, etc checking fitness during gate pass process

4. Leadership message during ‘Mass Tool Box’ talk to

motivate the entire team for strengthening safety culture

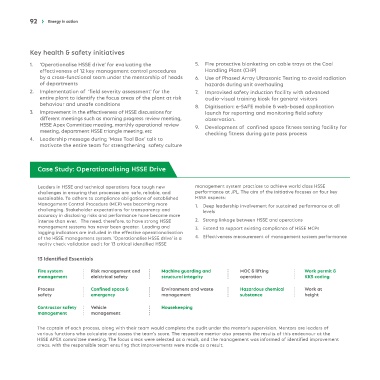

Case Study: Operationalising HSSE Drive

Leaders in HSSE and technical operations face tough new management system practices to achieve world class HSSE

challenges in ensuring that processes are safe, reliable, and performance at JPL. The aim of the initiative focuses on four key

sustainable. To adhere to compliance obligations of established HSSE aspects:

Management Control Procedure (MCP) was becoming more 1. Deep leadership involvement for sustained performance at all

challenging. Stakeholder expectations for transparency and levels

accuracy in disclosing risks and performance have become more

intense than ever. The need, therefore, to have strong HSSE 2. Strong linkage between HSSE and operations

management systems has never been greater. Leading and 3. Extend to support existing compliance of HSSE MCPs

lagging indicators are included in the effective operationalisation

of the HSSE management system. ‘Operationalise HSSE drive’ is a 4. Effectiveness measurement of management system performance

reality check validation audit for 13 critical identified HSSE

13 Identified Essentials

Fire system Risk management and Machine guarding and MOC & lifting Work permit &

management elelctrical safety structural integrity operation KKS coding

Process Confined space & Environment and waste Hazardous chemical Work at

safety emergency management substance height

Contractor safety Vehicle Housekeeping

management management

The captain of each process, along with their team would complete the audit under the mentor's supervision. Mentors are leaders of

various functions who calculate and assess the team's score. The respective mentor also presents the results of this endeavour at the

HSSE APEX committee meeting. The focus areas were selected as a result, and the management was informed of identified improvement

areas, with the responsible team ensuring that improvements were made as a result.