Page 45 - Apraava Energy Report_01-73

P. 45

Apraava Sustainability Report 2020-2021 45

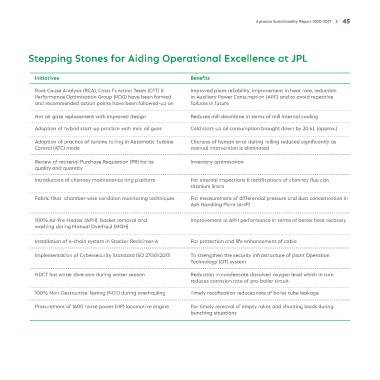

Stepping Stones for Aiding Operational Excellence at JPL

Initiatives Benefits

Root Cause Analysis (RCA), Cross Function Team (CFT) & Improved plant reliability, improvement in heat rate, reduction

Performance Optimisation Group (POG) have been formed in Auxiliary Power Consumption (APC) and to avoid repetitive

and recommended action points have been followed-up on failures in future

Hot air gate replacement with improved design Reduces mill downtime in terms of mill internal cooling

Adoption of hybrid start-up practice with mini oil guns Cold start-up oil consumption brought down by 20 kL (approx.)

Adoption of practice of turbine rolling in Automatic Turbine Chances of human error during rolling reduced significantly as

Control (ATC) mode manual intervention is eliminated

Review of material Purchase Requisition (PR) for its Inventory optimisation

quality and quantity

Introduction of chimney maintenance ring platform For internal inspections & rectifications of chimney flue can

titanium liners

Fabric filter chamber-wise condition monitoring techniques For measurement of differential pressure and dust concentration in

Ash Handling Plant (AHP)

100% Air Pre-Heater (APH) basket removal and Improvement in APH performance in terms of better heat recovery

washing during Manual Overhaul (MOH)

Installation of e-chain system in Stacker Reclaimer-A For protection and life enhancement of cable

Implementation of Cybersecurity Standard ISO 27001:2013 To strengthen the security infrastructure of plant Operation

Technology (OT) system

NDCT hot water diversion during winter season Reduction in condensate dissolved oxygen level which in turn

reduces corrosion rate of pre-boiler circuit

100% Non-Destructive Testing (NDT) during overhauling Timely rectification reduces rate of boiler tube leakage

Procurement of 1600 horse power (HP) locomotive engine For timely removal of empty rakes and shunting loads during

bunching situations