Page 48 - Balmer Lawrie Sustainability Report 2022_Single Pages

P. 48

Energy Management

Energy is the primary resource in operating our business processes. We use energy resources very responsibly considering

sustainable development. Technological advancement has been done in business processes to use energy resources

efficiently. Additional efforts have been taken to increase the use of renewable energy sources like the installation of solar

panels and thereby reducing carbon emissions.

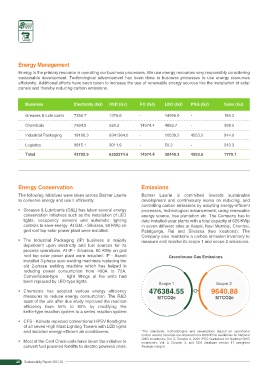

Business Electricity (GJ) HSD (GJ) FO (GJ) LDO (GJ) PNG (GJ) Solar (GJ)

Greases & Lubricants 7356.7 1378.6 - 14996.0 - 184.2

Chemicals 7364.9 520.2 14574.4 4862.7 - 398.5

Industrial Packaging 19166.3 6341364.0 - 10539.5 4553.5 944.0

Logistics 9815.1 9011.9 - 50.2 - 243.3

Total 43702.9 6352274.6 14574.4 30448.3 4553.5 1770.1

Energy Conservation Emissions

The following initiatives were taken across Balmer Lawrie Balmer Lawrie is committed towards sustainable

to conserve energy and use it efficiently: development and continuously works on reducing, and

controlling carbon emissions by adopting energy-efficient

• Greases & Lubricants (G&L) has taken several energy processes, technological advancement, using renewable

conservation initiatives such as the installation of LED energy source, tree plantation etc. The Company has to

lights, occupancy sensors and automatic lighting date installed solar plants with a total capacity of 626 KWp

controls to save energy. At G&L - Silvassa, 50 KWp on in seven different sites at Asaoti, Navi Mumbai, Chennai,

grid roof top solar power plant were installed. Patalganga, Rai and Silvassa (two locations). The

Company also maintains a carbon emission inventory to

• The Industrial Packaging (IP) business is majorly measure and monitor its scope 1 and scope 2 emissions.

dependent upon electricity and fuel sources for its

process operations. At IP - Silvassa, 50 KWp on grid

roof top solar power plant were installed. IP - Asaoti Greenhouse Gas Emissions

installed 3-phase auto welding machines replacing the

old 2-phase welding machine which has helped in

reducing power consumption from 400A to 72A.

Conventional-type light fittings at the units had

been replaced by LED-type lights. Scope 1 Scope 2

• Chemicals has adopted various energy efficiency 476384.55 9640.88

measures to reduce energy consumption. The R&D MTCO2e MTCO2e

team of the unit after due study improved the reaction

efficiency from 55% to 85% by modifying the

kettle-type reaction system to a series reaction system.

• CFS - Kolkata replaced conventional HPSV floodlights

of all seven High Mast Lighting Towers with LED lights

and installed energy-efficient air conditioners. *The standards, methodologies and assumptions (based on operational

control used to calculate are obtained from 2006 IPCC Guidelines for National

• Most of the Cold Chain units have taken the initiative to GHG Inventories, Vol. 2, Chapter 2, 2006 IPCC Guidelines for National GHG

Inventories, Vol. 2, Chapter 3, and CEA database version 17 (weighted

convert fuel powered forklifts to electric powered ones. Average margin)

48 Sustainability Report 2021-22