Page 120 - 1-37

P. 120

TRANSFORMING TRANSFORMING TRANSFORMING

SUSTAINABILITY REPORT FY 2023 COMMUNITIES THE PLANET THE WORKPLACE

Decarbonization of alumina refinery and transitioning to green alumina manufacture

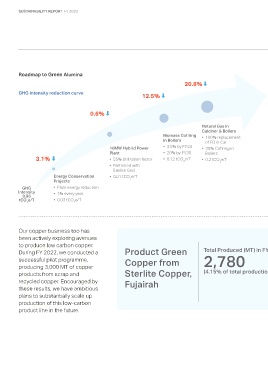

Roadmap to Green Alumina

20.8%

0.60

GHG Intensity reduction curve

12.5% tCO e/T

2

By FY30

To achieve our goal of reducing overall In FY 2022-23, significant progress

Green

0.6% Alumina GHG emissions we are first transitioning was achieved towards improving

our most emission-intensive production energy efficiency and sustainability.

Natural Gas in lines to greener energy sources. Our More than 3,200 LED lights were

Calciner & Boilers

Biomass Cofiring • 100% replacement alumina refinery at Lanjigarh is making installed during the year, accompanied

in Boilers of FO in Cal. this shift along with building capabilities by the implementation of more than 5

10MW Hybrid Power • 3.5% by FY24 • 30% Cofiring in for the production of Green Alumina. Variable Frequency Drives (VFDs), and

Plant • 20% by FY30 Boilers the adoption of Advanced Process

3.1% • 55% Utilization factor • 0.12 tCO e/T • 0.2 tCO e/T Making this shift involves a Control (APC) systems in key units.

2

2

• Partnered with comprehensive approach covering CO Additionally, measures like increased

Sterlite Grid emissions reduction, transitioning to 2 net liquor productivity, implementation

Energy Conservation • 0.01 tCO e/T more sustainable practices and also of an Acid Wash system, reduction in

2

Projects annually decreasing specific energy coal consumption, biomass firing in

GHG • Plant energy reduction

Intensity • 1% every year consumption by 1%. At the operational boilers, green power import, and a

0.96 level, this means reducing specific steam decrease in specific energy

tCO e/T • 0.03 tCO e/T

2 2 and fuel oil consumption, specific consumption to 7.16 GJ/T were also

electrical energy reduction, and specific accomplished, demonstrating a

greenhouse gas emissions reduction. strong frontline commitment to

This is being done by optimizing energy efficiency and environmental

Our copper business too has processes, implementing sustainability.

been actively exploring avenues energy-efficient technologies, and

exploring alternative energy sources.

to produce low carbon copper. The cumulative impact of all these

During FY 2022, we conducted a Product Green Total Produced (MT) in FY23 measures is expected to significantly

successful pilot programme, Copper from 2,780 bring down the environmental footprint of

producing 3,000 MT of copper the alumina refinery.

products from scrap and Sterlite Copper, (4.15% of total production)

recycled copper. Encouraged by Fujairah Additionally, efforts are focused on

these results, we have ambitious improving the station heat rate in the

Combined Gas and Power Plants (CGPP)

plans to substantially scale up associated with the refinery. By

production of this low-carbon upgrading heat recovery systems,

product line in the future. optimizing combustion processes, and

enhancing overall plant efficiency, the

goal is to maximize energy generation

while minimizing emissions and waste.

Further, auxiliary consumption in CGPP is

also targeted for reduction.

61