Page 67 - Apraava Energy Report_01-73

P. 67

Apraava Sustainability Report 2020-2021 67

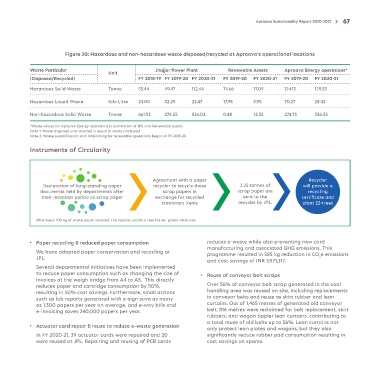

Figure 20: Hazardous and non-hazardous waste disposed/recycled at Apraava’s operational locations

Waste Particular Jhajjar Power Plant Renewable Assets Apraava Energy operations*

Unit

(Disposed/Recycled) FY 2018-19 FY 2019-20 FY 2020-21 FY 2019-20 FY 2020-21 FY 2019-20 FY 2020-21

Hazardous Solid Waste Tonne 55.44 49.47 112.44 74.66 17.09 124.13 129.53

Hazardous Liquid Waste Kilo Litre 24.00 52.29 22.47 17.98 5.95 70.27 28.42

Non-hazardous Solid Waste Tonne 661.92 274.25 324.02 0.48 12.33 274.73 336.35

*Waste values for Apraava Energy operations is summation of JPL and Renewable assets

Note 1: Waste disposed and recycled is equal to waste produced

Note 2: Waste quantification and monitoring for renewable operations began in FY 2019-20

Instruments of Circularity

Agreement with a paper Recycler

Declaration of long-standing paper recycler to recycle these 2.25 tonnes of will provide a

documents held by departments after scrap papers in scrap paper are recycling

their retention period as scrap paper exchange for recycled sent to the certificate and

stationary items recycler by JPL. plant 22-trees

#For every 100 kg of waste paper recycled, the recycler plants a tree for our green initiatives

• Paper recycling & reduced paper consumption reduces e-waste while also preventing new card

manufacturing and associated GHG emissions. This

We have adopted paper conservation and recycling at programme resulted in 585 kg reduction in CO e emissions

JPL. 2

and cost savings of INR 3,971,317.

Several departmental initiatives have been implemented

to reduce paper consumption such as changing the size of • Reuse of conveyor belt scraps

invoices at the weigh bridge from A4 to A5. This directly

reduces paper and cartridge consumption by 50%, Over 56% of conveyor belt scrap generated in the coal

resulting in 50% cost savings. Furthermore, small actions handling area was reused on site, including replacements

such as lab reports generated with e-sign save as many in conveyor belts and reuse as skirt rubber and lean

as 1,300 papers per year on average, and e-way bills and curtains. Out of 1,465 metres of generated old conveyor

e-invoicing saves 240,000 papers per year. belt, 816 metres were reclaimed for belt replacement, skirt

rubbers, and wagon tippler lean curtains, contributing to

a total reuse of old belts up to 56%. Lean curtains not

• Actuator card repair & reuse to reduce e-waste generation only protect lean plates and wagons, but they also

In FY 2020-21, 39 actuator cards were repaired and 20 significantly reduce rubber pad consumption resulting in

were reused at JPL. Repairing and reusing of PCB cards cost savings on spares.